Operation Manual

Supply the tool with 6.2bar(90psi)of cleandry air at Higher pressure drastically reduces tool life

Connect tool to air line using approved hose and fittingswith air filterait regulator and air lubricator

Do not install a quick coupler directly into the tool

1.Vapor may causes inside of spare parts, and high speed running may causes damage; therefore, please put some Air Tool Oil from inlet into tools, then switch on power and let the tools empty run with low speed for few seconds.

2.The correct time to add pneumatic special oil is at least three times a day, and must be added every 2 hours and before and after use.

3.Check all screws. parts. quick coupler whether they loosed, leaked or defaced before operating, to avoid danger, don't let the sander empty run.

4.Don't throw or cast tools randomly, improper usage will reduce the working life of tools, Always repair/change your tool with original parts which provided by local agent.

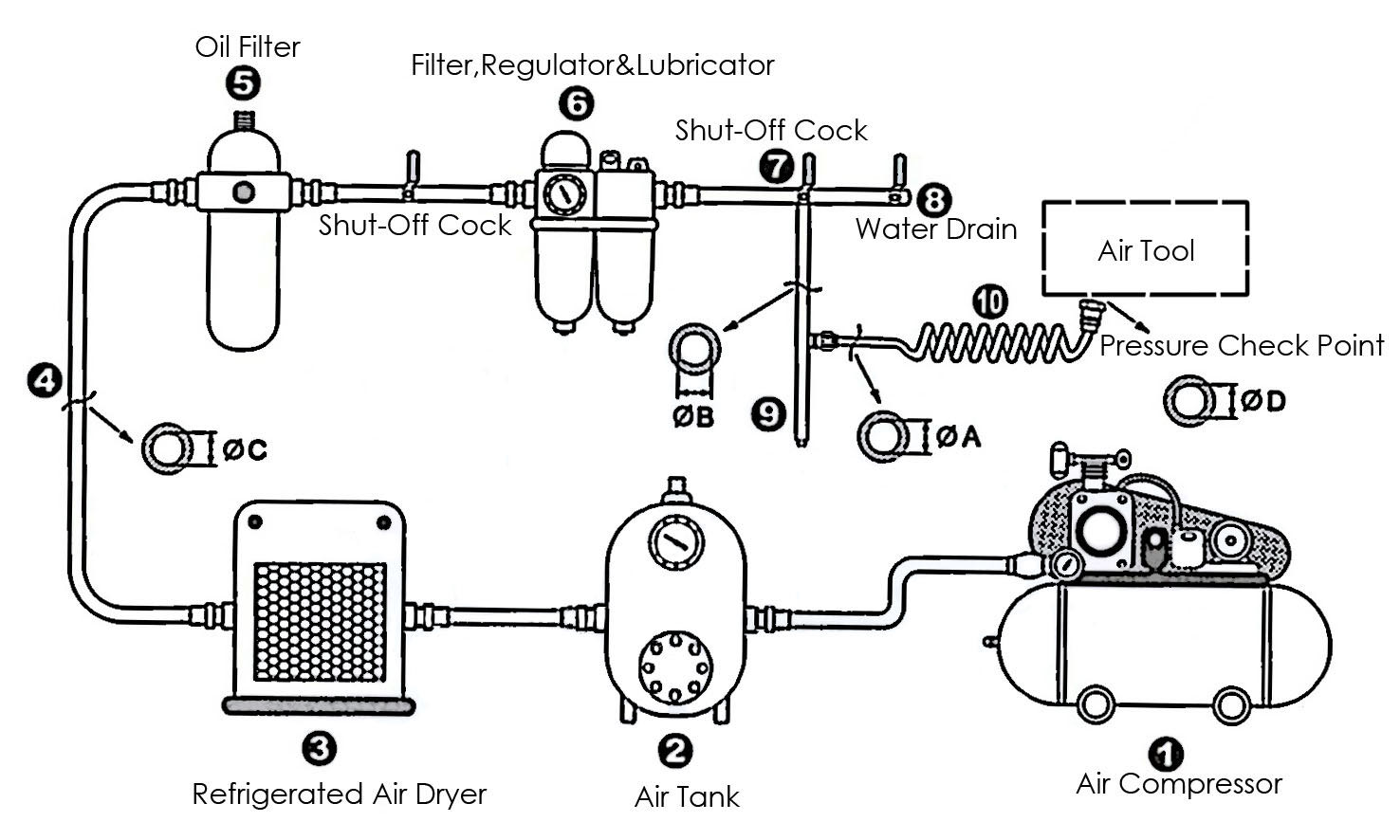

Piping diameters and length requirement:

★The diameter ФA required for the inlet pipe 10 is recommended on the specification table.

★The diameter ФB required for the branch pipe (from 7 to 9) should be 2 times as large as ФA. ФB=2x ФA

★The diameter ФC required for the primary air supply (from 1 to 8)should be 3 times as large as ФА. ФС = 3х ФА

★The length for the inlet pipe 10 should be less than 15 feet (4.5m).